TORQUE,

ANGLE,

LOAD

Micro Control designs and manufactures high quality, transient recorders, torque-tension test systems, ultrasonic tension sensors, torque angle transducers, load cells, torque-tension transducers tailored for fastener testing needs of numerous industries, including: Automotive, Aerospace, Defense, Medical, Power Generation, Process Control, Automation, and more.

TORQUE TENSION

TEST SYSTEMS

iPitch is an advanced multipurpose system designed to perform automated threaded fastener testing, joint analysis and calibration. It is comprised of a digital servo controller and a DC brushless motor mounted on a versatile sliding assembly. Together they deliver precise and accurate torque and speed that is required for threaded fastener testing. iPitch is used In conjunction with MC950, to provide control and data collection. A complete test system may also include a rotary torque-angle transducer, Bolt Tension Cell, Bolt Torque-Tension Cell or Ultrasonic Tension Sensors.

FASTENER

PERFORMANCE

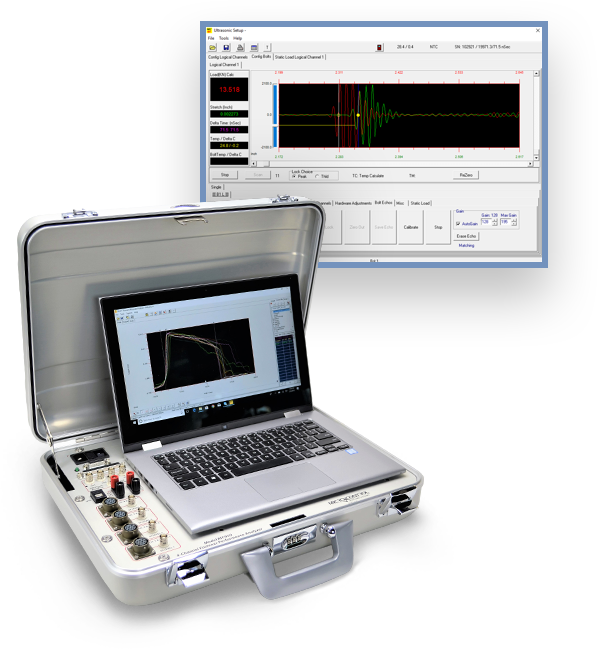

ANALYZER

Precision measurement of torque, angle, load, and linear displacement is provided in the Standard MC950. Additionally ultrasonic MC950 can measure clamp load precisely in an actual joint, either dynamically (while tightening) or statically (pre-load) using our Ultrasonic Tension Sensors. It is a valuable tool for fastener engineers to study threaded fastener joint designs or they can analyze the operation of nut-runners on the plant floor and in a laboratory environment. The MC950 Transient Recorder Analyzer is an indispensable tool for the fastener engineer, boasting the most diverse capabilities of any other transient recorder on the market.

Bolt Torque

Tension Cells

Bolt Tension and Bolt Torque-Tension Load Cells use a full bridge strain gage design. This complete line of fastener testing load cells provides a signal proportional to the tension developed in a test fastener when the tightening torque is applied. In addition, the Bolt torque-tension version, measures the thread torque simultaneously. The tension or torque-tension output signals from either type of load cell are read using MC950 transient recorder analyzer.

Torque Angle

transducers

The technology behind our torque sensors are strain gages. These gages are arranged into a Wheatstone bridge circuit, which converts the physical, mechanical torque into an electrical signal that can be filtered, displayed, and recorded for further processing. This very accurate electrical signal is proportional to the applied mechanical torque. Angle/Speed measurement is based on optical technology which provides a robust and precise measurement of shaft’s angular movement.

accessories

For our transducers, we provide corresponding couplings, pickups, cables, kits and much more.

Ultrasonic

sensors

Ultrasonic tension sensors (UTensor) are used to determine load on a fastener during or after assembly of a bolted joint. Load measurement is achieved by determining the change in the transit time of an ultrasonic shock wave along the length of the fastener (Time Delay). MC950 then interprets this time measurement into a given quantity of load and elongation. Time delay can be calibrated by MC950 to a known load using Bolt Tension cells. UTensor is glued to top or bottom of a fastener.